Despite my best efforts, the little Go Devil engine, just doesn't want to, er, go.

Since the last instalment (

Here) I've been busy trying to get the engine do more than "pop". I've been trying to actually get it to run. Ultimately, I discovered that the

rebuild I did on the carb just wasn't up to snuff. It was leaking out of places that it had no right to leak out of, and ultimately it was literally pouring fuel into the intake manifold, flooding out the engine.

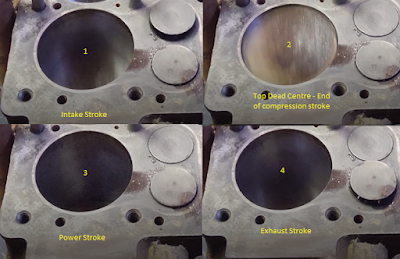

During this period, I also did a compression test to see if the engine was behaving, it turned out 80, 75, 60, 80 front to back, and on a cold engine. Not terrible, #3 was a little lower than I'd like, but we'll see what happens once it can warm up.

Since the carb ended up being a bust, I ended up ordering a Solex carburetor off Amazon. From what I've read, Mahindra makes these for Omix-Ada, and Mahindra has been playing the Jeep game for a while now. It's an interesting carb, in that it doesn't have a choke butterfly, it instead relies on a bypass valve of sorts that add extra fuel. Rather than choking the air, it adds more fuel. Interesting, and a mixed bag on reviews. For what it's worth, it's no longer flooding the engine, and it doesn't leak like the old YS Carb.

I got it installed and setup, it was practically a bolt on swap. I had to make a new fuel line adapter, but it was a minor inconvenience, and from what I understand, a result of having an m38 rather than a CJ3A.

So, did it work? Short answer, no, long answer, no. The engine still won't run. I went back to the drawing board. I double checked the points, electrical, spark plug gaps, well, everything related to a running engine. I then pinged some people smarter than I am, and the consensus seems to be my timing may be off. If you have any thoughts, feel free to drop them in the comments section.

At this point, stay tuned. I need to go dig out Grampa's timing gun, and pray that the distributor will come lose. I will get this thing running!

In other news, after staring at my two broken fuel pumps for a month, I had a thought - Could I take the good parts from them and make one working one? Turns out that's a yes. The broken casting on the "new" one practically crumbled in my hand during disassembly, but I managed to salvage the arm, diaphragm, and spring. I transplanted those into the old pump's lower assembly, and while I could've used the old pump's upper, the internal valves were shot. I decided to mate it to the newer upper. I think it's quite usable, and the pump works well. It's not installed on the engine yet, I don't need it during my attempts to start the Jeep, but it's ready.

With the cold weather, and well, life, my progress on the m38 has slowed a bit. I was due for an ICD (Implanted Cardioverter Defibrillator) replacement which was going to put me on light duty for a few weeks while I healed up, so my wife kicked me to the garage (my happy place).

With the cold weather, and well, life, my progress on the m38 has slowed a bit. I was due for an ICD (Implanted Cardioverter Defibrillator) replacement which was going to put me on light duty for a few weeks while I healed up, so my wife kicked me to the garage (my happy place).  I took the time to tackle the remaining wiring and mounting for my GM alternator conversion. I built the brackets earlier (Read about that here). I was never satisfied with the upper mount, so I had to come up with a better and more solid solution. A convenient piece of tube and a switch from threaded rod with nuts to a bolt really changed it for the better.

I took the time to tackle the remaining wiring and mounting for my GM alternator conversion. I built the brackets earlier (Read about that here). I was never satisfied with the upper mount, so I had to come up with a better and more solid solution. A convenient piece of tube and a switch from threaded rod with nuts to a bolt really changed it for the better.  For the wiring, rather than a dash light, I wired a diode inline to excite the alternator when the ignition coil is engaged. The diode will prevent feedback when I shut it off. A short universal battery cable from Princess Auto completed the wiring to the positive on the battery. Don't be like me, remember it goes to the Batt terminal, not the ground bolt on the alternator (Yeah, that was fun)

For the wiring, rather than a dash light, I wired a diode inline to excite the alternator when the ignition coil is engaged. The diode will prevent feedback when I shut it off. A short universal battery cable from Princess Auto completed the wiring to the positive on the battery. Don't be like me, remember it goes to the Batt terminal, not the ground bolt on the alternator (Yeah, that was fun)